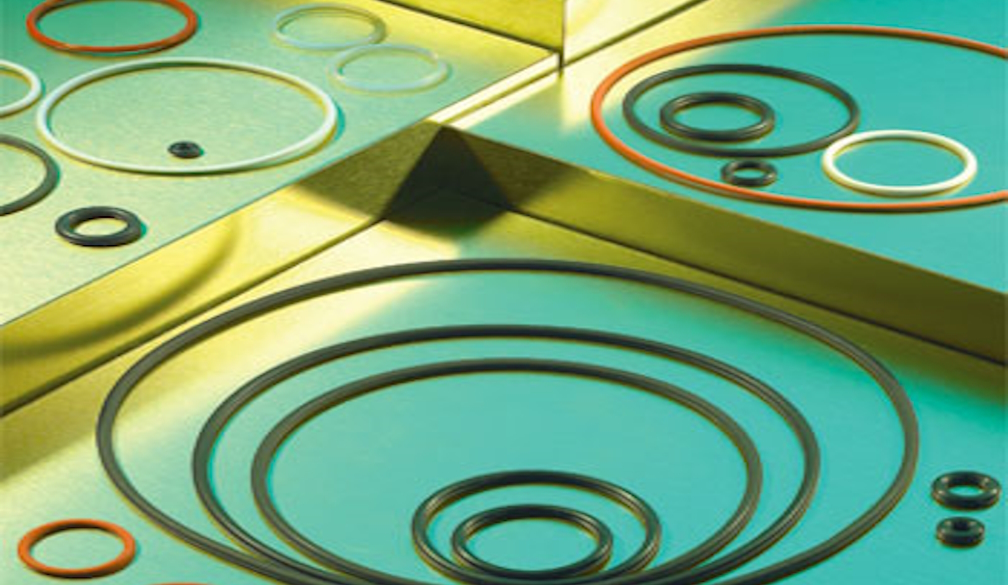

The Small Parts That Keep Big Industries Moving: Why O-Rings Matter More Than You Think

In industries where hygiene and precision are non-negotiable, the smallest parts often carry the heaviest responsibility.

A brewer once joked that a twenty-cent seal nearly cost him twenty thousand dollars. The culprit? A tiny O-ring hidden inside a pump that failed mid-production, letting an entire batch of beer go to waste. It’s a reminder that in industries where hygiene and precision are non-negotiable, the smallest parts often carry the heaviest responsibility.

More Than Just a Seal

At their core, O-rings are designed to create an airtight or watertight seal between two surfaces. It sounds simple, but in practice, their role is anything but. Without a properly fitted O-ring, even the most advanced production system can grind to a halt. A single leak can contaminate a batch, waste product, or compromise hygiene standards, all of which can cost time and money. That’s why choosing the right O-ring is more than just a technical detail; it’s an essential part of ensuring efficiency and safety across industries.

They might be small, but their impact is huge. Think of them as the unsung stagehands of production: invisible to the audience but critical to the performance.

Silicone and Rubber: Two Trusted Options

The food and beverage industry relies heavily on O-rings because of their versatility and durability. Two of the most widely used options are silicone o rings and the rubber o ring.

Silicone is highly valued for its ability to perform under extreme temperatures. From the heat of pasteurisation to the chilling environments of cold storage, silicone o rings maintain their shape and flexibility without breaking down. They also resist a wide range of chemicals, making them ideal for cleaning and sterilisation processes that are part of everyday operations.

The rubber o ring, meanwhile, remains a staple because of its excellent sealing properties, resilience, and affordability. These rings provide a strong, reliable seal for systems that operate under pressure, ensuring liquids and gases stay exactly where they should. Their toughness makes them a dependable choice for countless day-to-day applications in food and beverage plants across the country.

Designed for Precision and Reliability

What makes O-rings so indispensable isn’t just their material but the precision with which they’re made. A fraction of a millimetre can make the difference between a perfect seal and a costly leak. That’s why quality control is critical. Each silicone o rings or rubber o ring must be manufactured to exacting tolerances, ensuring they can withstand pressure, temperature shifts, and constant use without losing their effectiveness.

This precision engineering allows O-rings to work quietly in the background, doing their job day after day. From pumps circulating thousands of litres to delicate pharmaceutical equipment handling sensitive compounds, their reliability keeps production moving smoothly and safely.

Small Parts, Big Impact

It’s easy to underestimate the value of such a small component, but O-rings are truly the unsung heroes of production lines. They protect product integrity, ensure equipment efficiency, and help businesses avoid costly downtime. Without them, even the most sophisticated systems would falter.

So while O-rings might not be the star of the show, their role in keeping big industries moving is undeniable. From sealing pumps in beverage plants to protecting systems in pharmaceutical labs, they provide the quiet reliability that underpins the success of some of Australia’s most important sectors, proving once again that it’s often the smallest pieces that hold the whole picture together.